Description

Case Cx210, Cx230, Cx240 Crawler Excavators Service Repair Manual

Make: Case

Catalog: Heavy Machinery

Model: Cx210, Cx230, Cx240

Pages: 648

Format: PDF

Size: 103mb

Language: English

Requirements: Adobe PDF Reader & WinZip

Compatibility: All Versions of Windows & Mac/IPAD

Complete digital official shop manual contains service, maintenance, and troubleshooting information for the Case Cx210, Cx230, Cx240 Crawler Excavators. Diagnostic and repair procedures are covered in great detail to repair, maintain, rebuild, refurbish or restore your Case Cx210, Cx230, Cx240 Crawler Excavators like a professional mechanic in local service/repair workshop. This cost-effective quality manual is 100% complete and intact as should be without any missing pages. It is the same factory shop manual used by dealers that guaranteed to be fully functional to save your precious time.

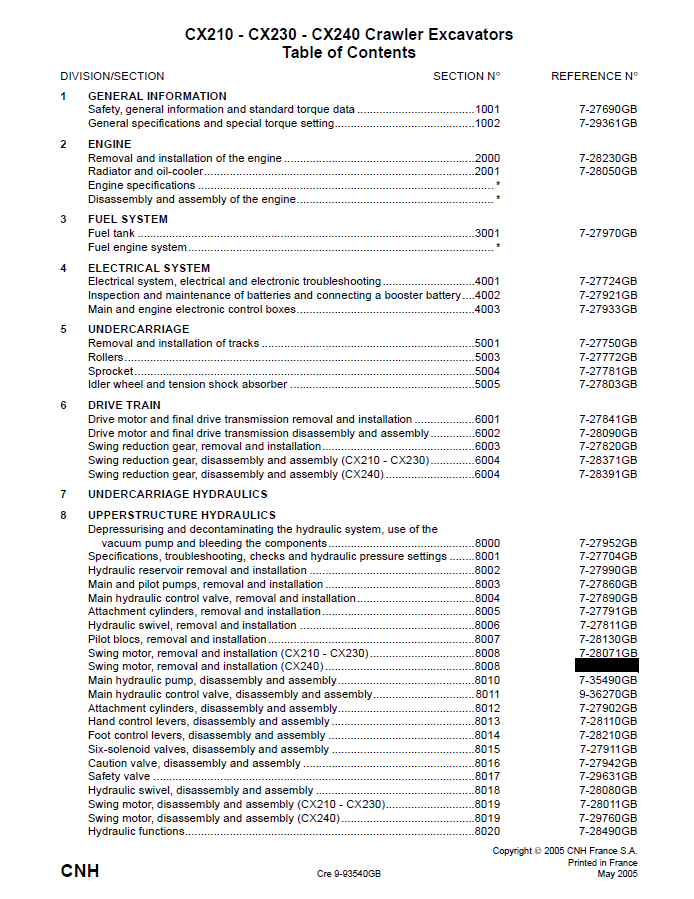

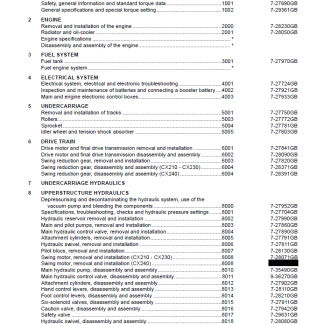

CONTENTS:

GENERAL INFORMATION

SECTION 1001 – Safety, general information and standard torque data

SECTION 1002 – General specifications and special torque setting

ENGINE

SECTION 2000 – Removal and installation of the engine

SECTION 2001 – Radiator and oil-cooler

Engine specifications – Consult the Engine Service Manual

Disassembly and assembly of the engine – Consult the Engine Service Manual

FUEL SYSTEM

SECTION 3001 – Fuel tank

Fuel engine system – Consult the Engine Service Manual

ELECTRICAL SYSTEM

SECTION 4001 – Electrical system, electrical and electronic troubleshooting

SECTION 4002 – Inspection and maintenance of batteries and connecting a booster battery

SECTION 4003 – Main and engine electronic control boxes

UNDERCARRIAGE

SECTION 5001 – Removal and installation of tracks

SECTION 5003 – Rollers

SECTION 5004 – Sprocket

SECTION 5005 – Idler wheel and tension shock absorber

DRIVE TRAIN

SECTION 6001 – Drive motor and final drive transmission removal and installation

SECTION 6003 – Drive motor and final drive transmission disassembly and assembly

SECTION 6004 – Swing reduction gear, disassembly and assembly (CX210-CX230)

SECTION 6004 – Swing reduction gear, disassembly and assembly (CX240)

UNDERCARRIAGE HYDRAULICS

UPPERSTRUCTURE HYDRAULICS

SECTION 8000 – Depressurising and decontaminating the hydraulic system, use of the vacuum pump and bleeding the components

SECTION 8001 – Specifications, troubleshooting, checks and hydraulic pressure settings

SECTION 8002 – Hydraulic reservoir removal and installation

SECTION 8003 – Main and pilot pumps, removal and installation

SECTION 8004 – Main hydraulic control valve, removal and installation

SECTION 8005 – Attachment cylinders, removal and installation

SECTION 8006 – Hydraulic swivel, removal and installation

SECTION 8007 – Pilot blocs, removal and installation

SECTION 8008 – Swing motor, removal and installation (CX210-CX230)

SECTION 8008 – Swing motor, removal and installation (CX240)

SECTION 8010 – Main hydraulic pump, disassembly and assembly

SECTION 8011 – Main hydraulic control valve, disassembly and assembly

SECTION 8012 – Attachment cylinders, disassembly and assembly

SECTION 8013 – Hand control levers, disassembly and assembly

SECTION 8014 – Foot control levers, disassembly and assembly

SECTION 8015 – Six-solenoid valves, disassembly and assembly

SECTION 8016 – Caution valve, disassembly and assembly

SECTION 8017 – Safety vave

SECTION 8018 – Hydraulic swivel, disassembly and assembly

SECTION 8019 – Swing motor, disassembly and assembly (CX210-CX230)

SECTION 8019 – Swing motor, disassembly and assembly (CX240)

SECTION 8020 – Hydraulic functions

UPPERSTRUCTURE

SECTION 9000 – Quick coupler

SECTION 9002 – Upperstructure, turntable and counterweight

SECTION 9003 – Boom, dipper and bucket

SECTION 9004 – Seat and seat belt

SECTION 9005 – Cab and cab equipment

SECTION 9006 – Air conditioning troubleshooting

Large format hydraulic and electrical schematics

Ten Jet Foei –

“Great service, will definitely use your services again.”